About

Precision

Dip Coating

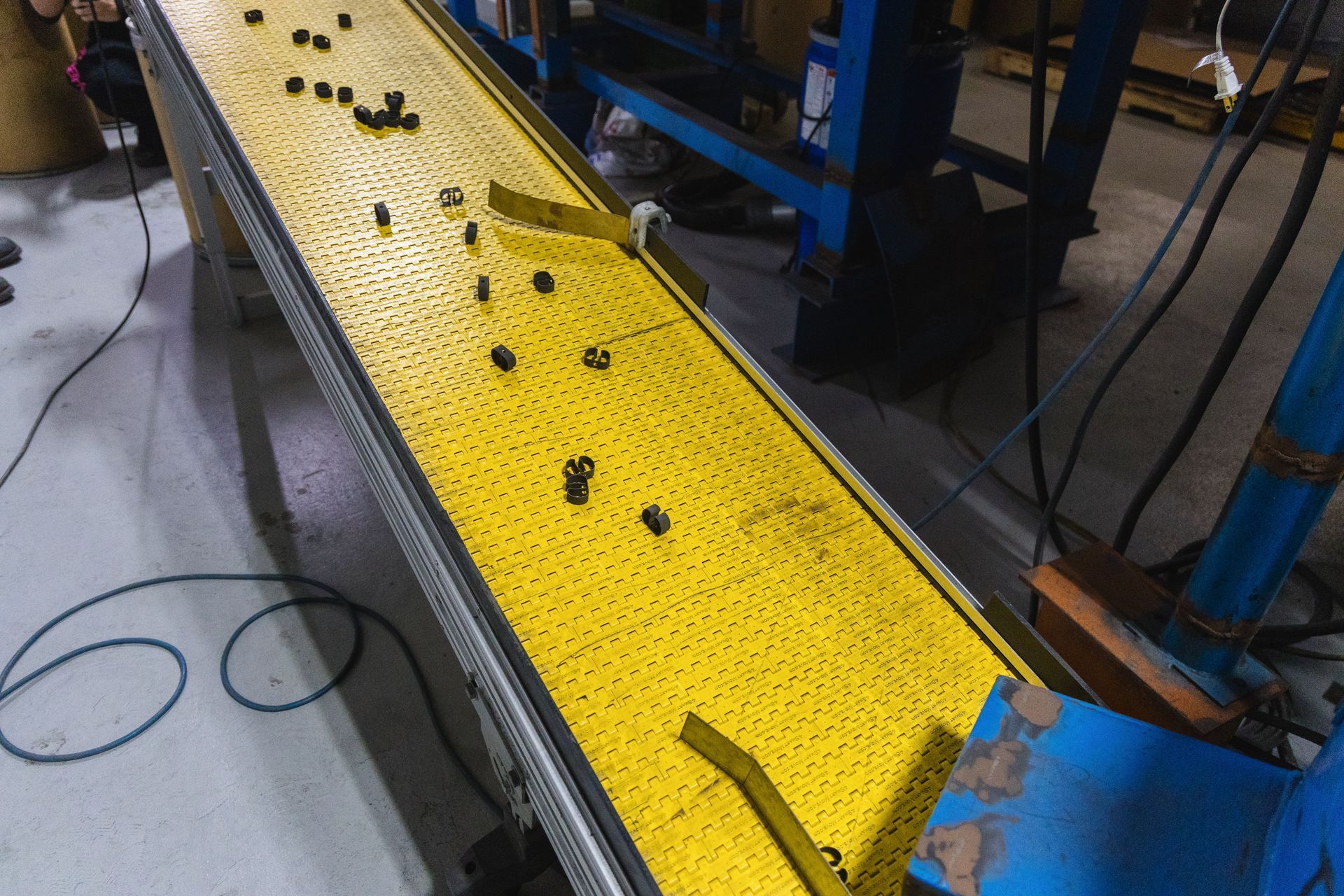

Our Facilty

Our state-of-the-art facility is the heart of our operations where innovation meets precision. Staffed by skilled technicians, our workspace is equipped with advanced machinery for dip coating, ensuring each project is handled with utmost care and expertise.

We are proud to be associated with:

What OuR Clients Say About Precision Dip COating

Frequently Asked Questions

What measures are taken at Precision Dip Coating's facility to ensure the quality of the coatings?

We implement rigorous quality control procedures at every stage of production, from initial material inspection to the final coating application, ensuring every finished product meets our high-quality standards.

Can I schedule a visit to Precision Dip Coating's facility to see the operations?

Yes, we welcome clients to visit our facility to witness our operations firsthand. Please contact us to schedule a tour and discuss your specific project needs with our team.

How does Precision Dip Coating ensure safety and environmental compliance at its facility?

Safety and compliance are paramount. Our facility operates in strict adherence to safety regulations and environmental guidelines, ensuring a safe workplace and sustainable operations.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Our Blog