Unlock the Potential of Nylon Coating for Your Products

Strong and Flexible Coating

Discover the strength and flexibility of Nylon coating, a leading choice for enhancing product durability and performance across a broad spectrum of industries. Renowned for its robustness, Nylon coatings provide an easy-to-clean, resistant surface that stands up to abrasion, wear, and a variety of chemicals. Ideal for applications requiring reliability and longevity, our Nylon coating services cater to a diverse range of needs—from automotive components to food processing equipment.

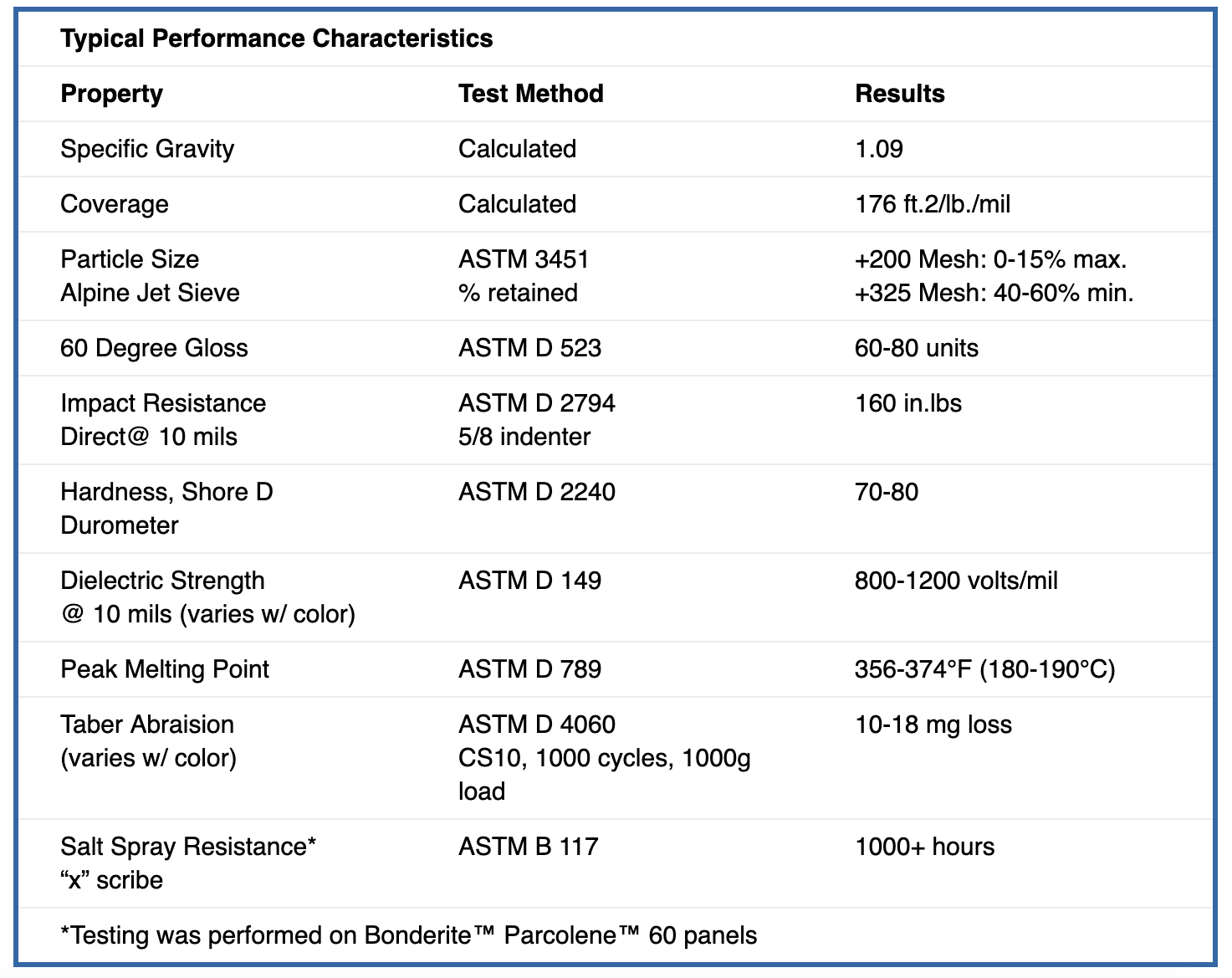

Nylon Coating Performance Characteristics

The Benefits of Nylon Coating

A nylon coating can be applied to a product using a fluidized bed powder process, electrostatically or via a maxi coat process. All methods offer an effective way to protect and coat metals functionally. Setting the product in a nylon powder bed creates a smooth and even coat in a single step and can eliminate the need for finishing work after the coating has formed to the surface. The end result is an attractive and glossy nylon coating that will help to protect the item from the environment, chemicals, abrasion, wear, and many other applications.

Nylon can offer several advantages when coated on a product:

Nylon Coating Applications

Nylon coatings offer durable, easy-to-clean finishes with outstanding resistance to abrasion, wear, chemicals, and solvents, along with excellent electrical properties and exterior durability. They feature a low friction coefficient and can be remelted for adjustments. Common uses include automotive parts, furniture, industrial pipes, food processing gear, marine hardware, shopping carts, material handling tools, and components like door parts and drawer slides.

Contact Precision Dip Coating for Nylon Coatings

For over three decades, the professional and experienced staff at Precision Dip Coating

have been providing clients across the nation with nylon coating services. From the preparation of the part/product to the physical coating and setting, our team has extensive knowledge when it comes to producing exceptional results that keep our clients satisfied and coming back! To learn more about our nylon coating services, do not hesitate to

contact us!

Contact Us

Contact Us

Related Services

For more information about our manufacturing services, call us at 203-805-4564 or visit ourcontact page.

Why Choose Us

Wondering why Precision Dip Coating should be your top choice for dip coating and molding services? Here's what sets us apart:

Industry Experience

Decades of Professional Expertise

Value-Added Services & Support

Beyond Service, Added Value Support

Integrated Design & Development

Expertise From Concept To Completion

From Prototype to Production

Turning Ideas Into Reality, Refining Craftsmanship

Frequently Asked Questions

What industries use nylon coating?

Nylon coatings are suitable for nearly any industry, but are most commonly used for applications which most benefit from its extreme durability, low friction, excellent chemical resistance, UV tolerance, and high performance in challenging conditions. These commonly include the medical, aviation & aerospace, automotive, industrial, and consumer goods industries.

Is nylon coating environmentally friendly?

Non-toxic and sustainable, nylon is naturally an eco-friendly coating solution. Because it protects metal so well, it also supports sustainability by prolonging the working life of the parts and products it coats.

How are nylon coatings applied?

Nylon coatings can be applied by electrostatic spray powder coating, or with a fluidized bed technique. Spray coating typically generates a thinner coat while fluid bed coating can offer a thicker coating.

Is nylon suitable as a sterilization coating?

Because it is non-absorbent, performs well in high temperatures, and maintains a durable, extremely smooth surface, nylon coatings are perfect choices for the unique demands of sterilization coatings.

How thick can nylon coatings be?

Nylon coatings typically range from about 0.0015″ to over 0.04″, making them an especially versatile option for protective coatings.

Our Blog