The Benefits of Nylon Coating

Learn More About the Environmentally Friendly Coating

Precision Dip Coating provides in-house design and development, quality engineering, and competitive pricing. We have twenty years of experience offering the best coated and molded products to a variety of industries. In order to help as many customers as possible, our team works hard to continuously improve our workforce, materials, and technologies.

What is Nylon Coating?

Nylon powder coating is an environmentally safe material derived from the oil of the castor plant. When combined with resins, the powder hardens into a resilient coat with a superior finish.

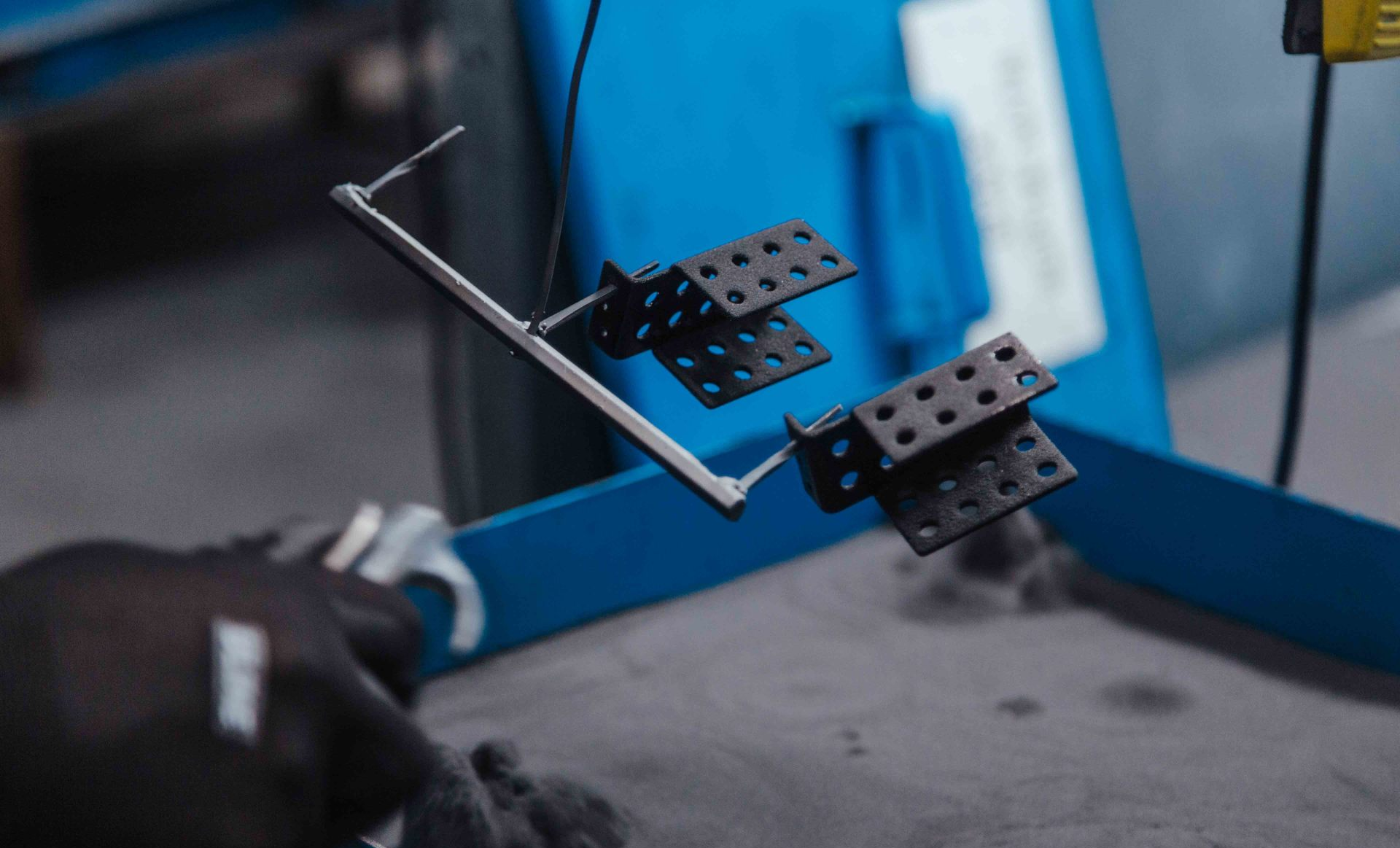

Nylon coating provides a performance standard of durability that few other materials can match. It has become the material of choice due to its unique properties. Nylon is especially used a lot in the appliance industries as well as for coating everything from automotive parts to medical equipment.

What Are the Advantages of Nylon Coating?

- Easy to clean

- Abrasion resistant

- Greater impact resistance

- Corrosion resistant

- Chemical resistant

- Noise reduction

- Environmentally friendly

- Renewable

- Recyclable

- Affordable cost to performance ratio

- Meets the standards of autoclaving requirements

What are Nylon Coating Applications?

There are two ways to apply nylon coating.

- Fluidized bed coating: An object is preheated and then dipped into a fluidized nylon powder which coats the part and is then cured.

- Electrostatic spray coating: An object is sprayed with a fluidized nylon powder at room temperature and is later heated then cured.

Common product applications for nylon coating include food processing materials, furniture, automotive equipment, medical equipment, industrial pipe and fittings, marine hardware, a variety of tools and utensils, and so much more.

Why Call Precision Dip Coating?

With Precision Dip Coating, you will save time and money on all your dip molding and coating needs. Contact us today, and let our team eliminate your supply chain problems and make your production idea a reality.