Comfort & Safety: Plastic Dipping Hand Tools

Hand tools are a necessity for countless projects both at home and at work, but they can be uncomfortable and even dangerous to use, especially for extended periods or in challenging environments. Plastisol dip coating is one easy, inexpensive, and very effective way to make hand tools safer and more comfortable.

What Is Plastisol Dip Coating?

One of the most common plastic coatings, plastisol is a combination of a plastic resin (usually polyvinyl chloride, aka PVC) and a chemical called a plasticizer which makes it soft and pliable. To apply a dip coating, the plastisol mixture is heated as is the tool or other part. The tool or part is then immersed partly or completely in the liquid plastisol then heat-cured to solidify the coating.

How Can Plastisol Dip Coating Enhance Safety & Comfort?

Plastisol dip coating offers a variety of improvements over bare metal hand tool handles, including:

Insulation

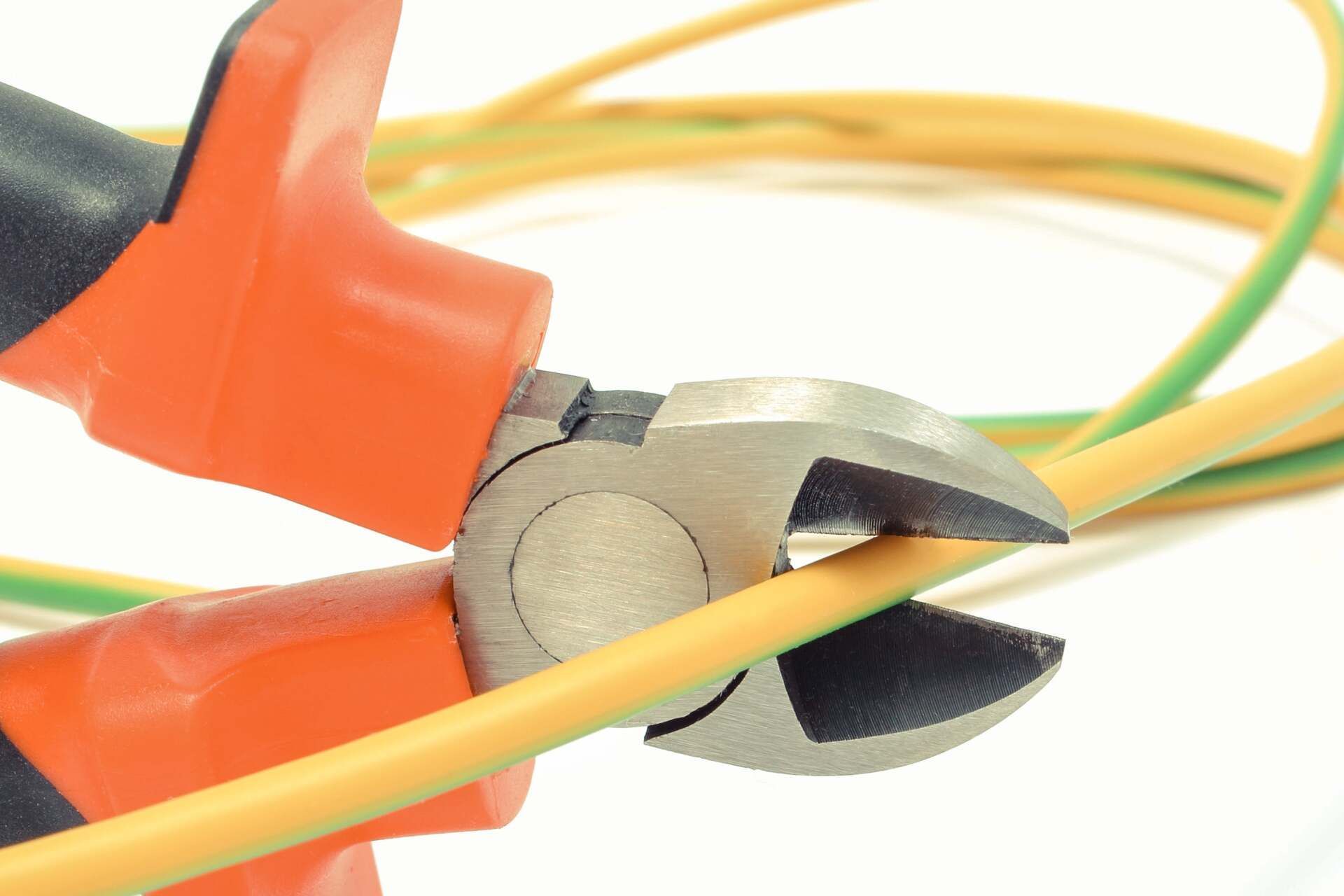

Plastisol coatings can insulate hands from overheated or icy cold metal. It is also an excellent electrical insulator, and is commonly used to coat tools used for high-voltage and other electrical work.

Cushioning

Because plastisol coatings have a naturally soft, rubbery feel, they offer some padding and vibration dampening which can help prevent discomfort and injury from noise and vibrations.

Improved Grip

Durable but soft even in very cold temperatures, plastisol coatings make slippery tool handles easier to grip in all types of conditions.

Visual Cues

With its ability to be tinted to match nearly any color and many special effects, plastisol handle coatings can be used for color-coding to ensure proper tool selection, and can offer enhanced visibility in poor or dark conditions.

Tool Protection

The protective layer plastisol provides can insulate valuable tools from being damaged by impacts, abrasions, chemical exposure, and more, helping keep tools reliable and safe for use.

At Precision Dip Coating, we take safety seriously, in our workplace and with every job we do for our customers. Contact us today to see how our plastic coating and molding services can improve safety for your products.