MEDICAL PLASTIC COATINGS

COMFORT & STERILIZATION

COATING FOR THE MEDICAL INDUSTRY

FREQUENTLY ASKED QUESTIONS ABOUT MEDICAL PLASTIC COATINGS

The unique requirements of the medical industry demand durable, hygienic, versatile coatings which provide the best safety and protection possible for healthcare workers and their patients. Plastic coatings are up to the challenge. Read more with some answers to frequent questions about plastic coatings for healthcare and medical applications.

-

Why is powder coating helpful for the medical industry?

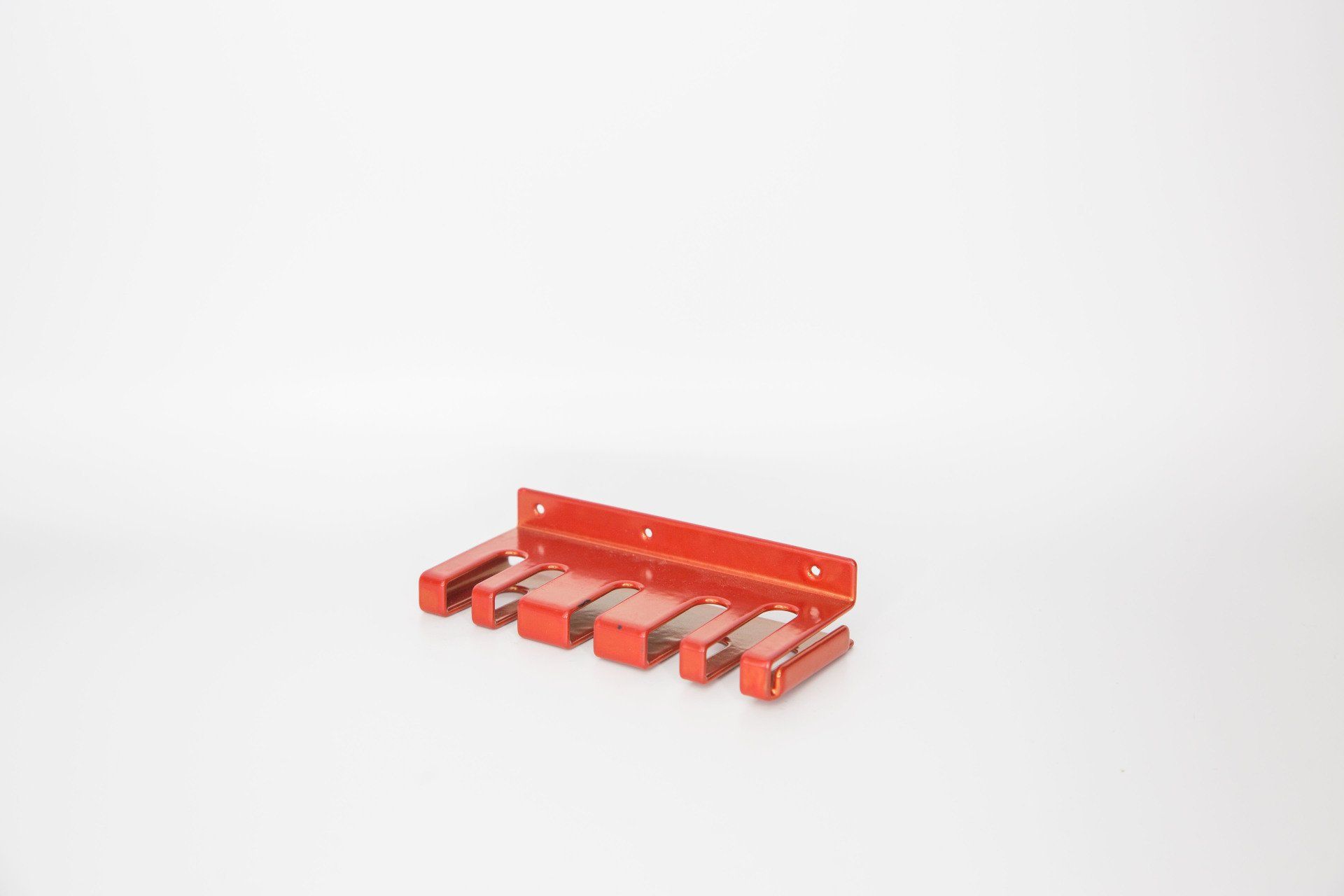

Plastic coatings offer benefits of safety, comfort, and protection for workers, patients, and equipment in the medical industry, including:

- Improved durability of tools and equipment

- Better resistance against chemical, corrosive, and other hazardous exposures

- Smoother, more comfortable, and easier-to-clean surfaces

- Enhanced antimicrobial and antibacterial protection

-

Is powder coating sterile?

Many powder coatings, such as epoxy and Halar™ provide very smooth surfaces which are well-suited to medical applications. When required, nylon sterilization coatings meet the exacting requirements for safety and durability needed with sterilization cases and other vital equipment.

-

How does plastic coating benefit healthcare workers?

Powder and dip coatings make PPE more protective, improve comfort with softer handles and grips, make surfaces easier to clean, and protect equipment from wear and damage.

-

What types of coatings are used for medical industry applications?

In addition to specialized sterilization coatings, nylon and Halar™ are commonly used to reduce friction and wear, epoxy is a popular coating for lab and equipment protection, and vinyl is commonly used on PPE and related fixtures. Plastisol dip coating adds a soft, comfortable coating for handles.

-

How do plastic coatings keep healthcare workers and patients safer?

Many plastics have innate antibacterial and antimicrobial characteristics, which improve safety along with smooth, resistant coatings which reduce opportunities for germs, bacteria, and debris to cling to medical devices and equipment.

LEARN MORE WITH OUR BLOGS

HAVE QUESTIONS?

Thinking of starting a project and want to know if we're the right fit to work with you? We would love to answer any question that you may have. Precision Dip Coating is located on 176 Chase River Rd, Waterbury, CT 06704, United States and can help you step in the right direction with your project. Additionally, you can email sales@precisiondipcoating.com for more information.

ISO 9001:2015 Certified

ABOUT

SERVICES

CONTACT US

CONTACT USThe information on this website is for general information purposes only. This information is not intended to create, and receipt or viewing does not constitute, a manufacturer and client relationship. Precision Dip Coating is licensed & insured for the job. Call 203-805-4564. Email with any questions you may have regarding this website, or anything associated with it.

All Rights Reserved. This website was designed, SEO optimized, and marketed by DeveloMark.