STERILIZATION COATING

LEADING STERILIZATION COATING MANUFACTURERS

WHAT DOES IT DO?

- 100% encapsulation of coated parts with no bare metal or hook scars

- Compliance with standards and regulations for sterilization

- Protection from oxidation and moisture

- Chemical and corrosion resistance

- Non-absorbency, making nylon an excellent choice for sterilization needs

- Durability, providing superior performance over prolonged use

- Excellent ability to withstand the high temperature and pressure of autoclave sterilization processes

- A very thin, smooth, even surface for improved safety and effectiveness

- Strength to resist impacts and abrasions

- Superior adhesion between the nylon coating and the metal substrate

- An environmentally friendly, sustainable, non-toxic coating

- Cost-effectiveness with the ability to provide excellent performance for extended use over time

FREQUENTLY ASKED QUESTIONS ABOUT STERILIZATION COATING

The specialized sanitary and hygiene demands of the medical and healthcare industry require powder coating that can safely protect metal tools and equipment during repeated use and high-temperature and pressure sterilization processes. Nylon sterilization coatings are up to the challenge. Here are some answers to common questions we've received about sterilization coatings.

-

What is sterilization coating made of?

Sterilization coating is applied with a type of synthetic polyamide (nylon).

-

How thick is sterilization coating?

Thin, even, smooth sterilization coatings typically range from about .005" (5 mils) to .04" (40 mils).

-

What makes sterilization coating effective?

Nylon offers a combination of qualities that make it particularly well suited for sterilization applications, including:

- Extreme smoothness

- 100% encapsulation

- Superior durability

- Non-toxic material

- Excellent longevity

- High heat tolerance

- Non-absorbent

- High pressure tolerance

- Chemical, moisture, and corrosion resistant

-

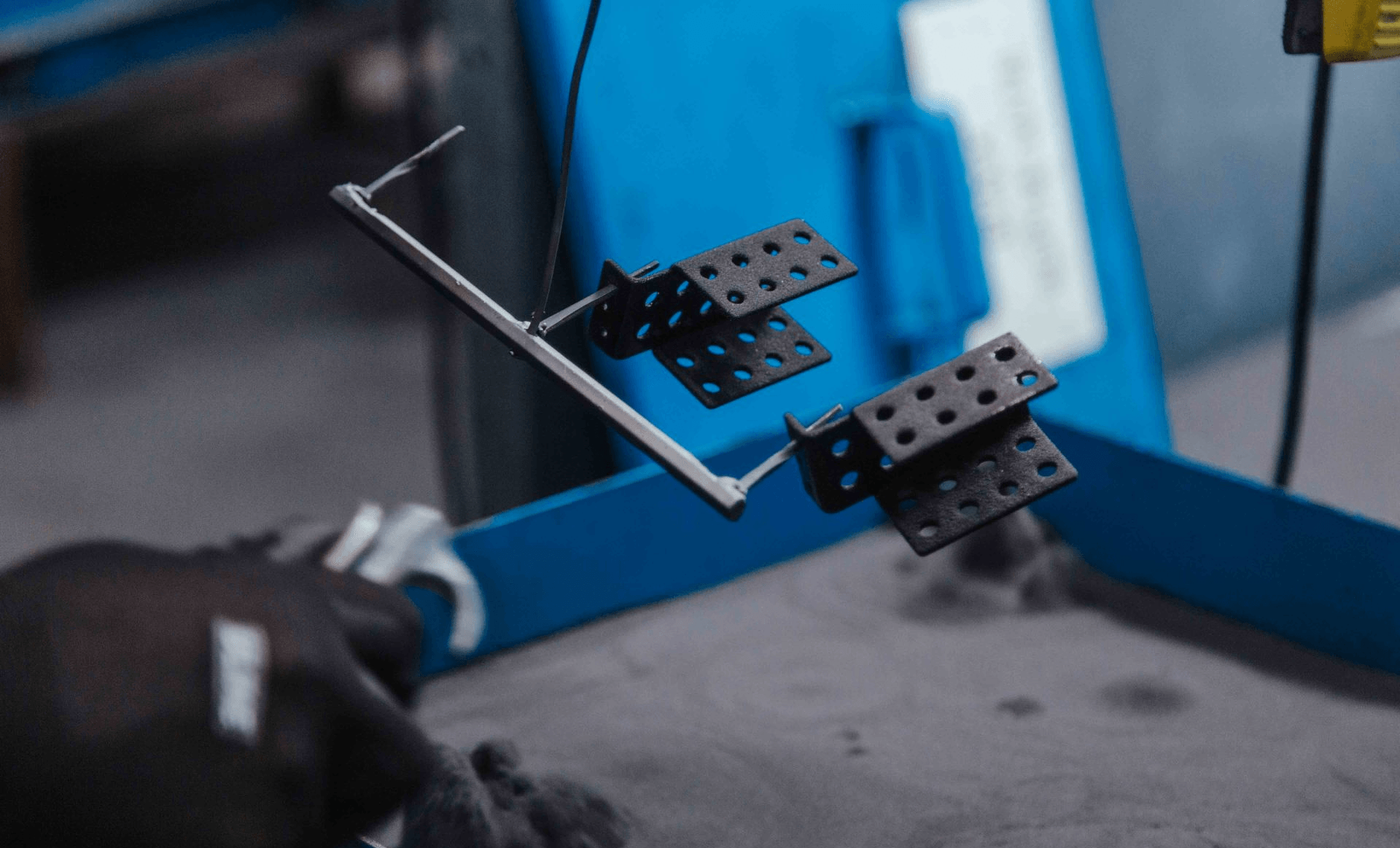

How is sterilization coating applied?

As with most powder coatings, sterilization coating can be applied by electrostatic spray or through fluidized bed techniques. Choosing between these application methods depends mainly on the shape and structure of the product being coated, and desired coating thickness.

-

What substrates are suitable for sterilization coating?

Because of the temperatures needed to cure sterilization coatings, substrates must be able to withstand that exposure. Typical substrates are made from various steel and aluminum alloys.

-

What industries use sterilization coating?

The medical industry uses sterilization coating most often, typically for surgical instrument cases and trays and other medical equipment which comes into direct patient contact. Truly, any industry requiring nylon's unique combination of physical, thermal, and mechanical characteristics will benefit from its many advantages.

LEARN MORE WITH OUR BLOGS

HAVE QUESTIONS?

Thinking of starting a project and want to know if we're the right fit to work with you? We would love to answer any question that you may have. Precision Dip Coating is located on 176 Chase River Rd, Waterbury, CT 06704, United States and can help you step in the right direction with your project. Additionally, you can email sales@precisiondipcoating.com for more information.

ISO 9001:2015 Certified

ABOUT

SERVICES

CONTACT US

CONTACT USThe information on this website is for general information purposes only. This information is not intended to create, and receipt or viewing does not constitute, a manufacturer and client relationship. Precision Dip Coating is licensed & insured for the job. Call 203-805-4564. Email with any questions you may have regarding this website, or anything associated with it.

All Rights Reserved. This website was designed, SEO optimized, and marketed by DeveloMark.