4 Reasons Powder Coating is Better than Traditional Wet Paint Techniques

Precision Dip Coating, in Connecticut, offers unmatched dip coating and molding services. The top-notch coating technology and dedicated staff ensure delivery of first-class and quality services to a variety of industries.

Have you ever wondered why industry experts rate powder coating over traditional wet painting techniques? To decipher this, you must first understand the difference between the two.

What's the Difference Between Powder Coating and Wet Painting?

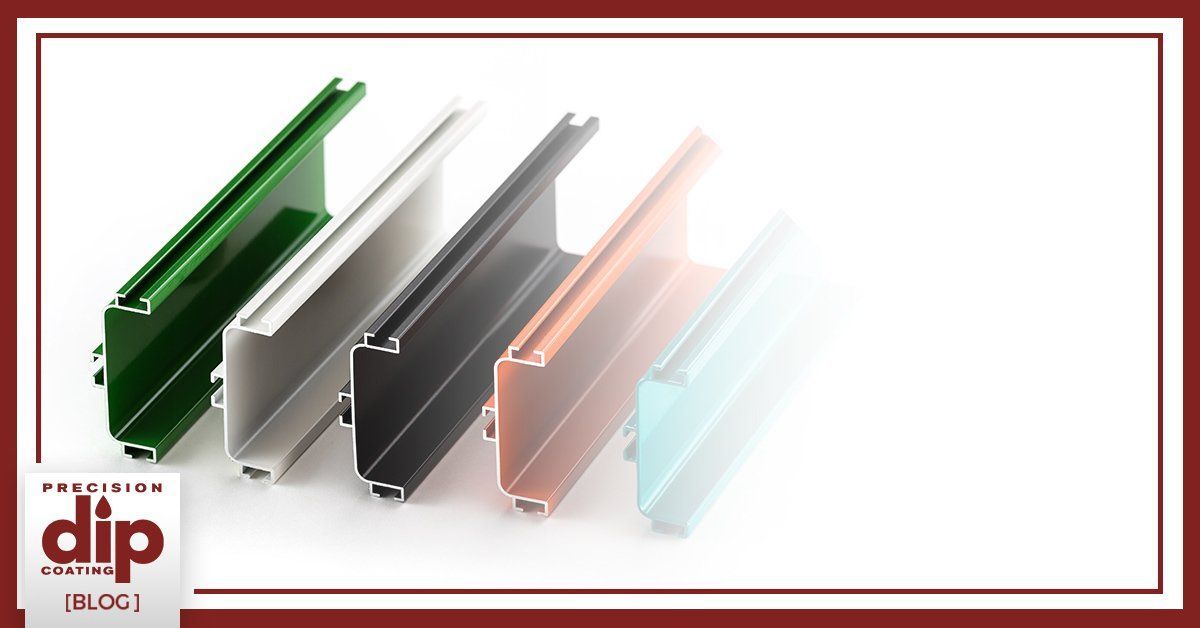

Powder coating uses heat to adhere a dry powder, whether epoxies, acrylics, polyesters, among others, to a surface. Wet painting, on the other hand, applies a layer of colored solution to a surface using a brush, or pressure applicant.

Why Powder Coating Is Better Than Traditional Wet Painting Techniques

Although on the face of it both powder coating and wet painting seem like alternative techniques for surface finishing and protection, the former accords more benefits. Find below four reasons why.

- Durability

Save yourself the hassle and costs of repainting every so often-especially if you live in extreme weather areas. Powder coating offers a sturdy and thick non-strip coat. Furthermore, the smooth durable layer protects the underlying surfaces saving you on repairs, replacement, and maintenance costs.

- Faster Application Speed

Unlike traditional wet painting techniques, powder coating can be automated and only requires a single layer application. The superior application speed comes in handy for extensive surface areas. Also, you spend less on material and labor costs.

- Environmentally Friendly

Fancy appealing to environment-conscious clients, and contribute to saving Mother Earth and enjoy a tax rebate while at it? Powder coating ranks under green technology due to relatively fewer toxins. Also you can retrieve over spray and recirculate in the hopper for use. Paint, on the contrary, contains several pollutants, especially volatile organic compounds and solvents.

- Safety

Solvents and volatile compounds in paints accelerate fires and chemical accidents, especially in industries and commercial buildings. Powder coatings, thanks to the absence of solvents and VOCs, are inert and safer.

A Company You Can Trust

With Precision Dip Coating, you enjoy trusted and tested 20 years experience in providing professional and informed assistance in all matters powder coating. Do contact us!