VINYL COATING

THE "WORKHORSE" POWDER COATING

EXCELLENT CHEMICAL RESISTANCE

- Corrosion protection

- Chemical resistivity

- Electrical insulation

- Abrasion / impact resistance

- Marine applications

- Dishwasher baskets

- Bus bars

- Patio furniture

- Outdoor fencing

- SCUBA gear

- Bicycle racks

FREQUENTLY ASKED QUESTIONS ABOUT VINYL COATING

Among coating options, vinyl coating is considered one of the best all-purpose coating materials. Versatile and budget-friendly, vinyl coatings are found in homes, businesses, industrial facilities, and everywhere in-between. Some frequently asked questions we receive about vinyl coatings are answered below.

-

Are vinyl coatings safe?

Vinyl coatings need plasticizer components which allow them to achieve the flexibility they require. Traditionally, plasticizers often contained phthalates, which can be harmful to those exposed to them. Newer formulations of vinyl coatings can be phthalate-free, making them a safe choice.

-

What's the difference between vinyl, plastisol, and PVC?

Vinyl powder coating and plastisol are two different but related types of polyvinyl chloride (PVC)-based coatings. Plastisol is a liquid at room temperature and typically applied in thicker coats by dipping, while vinyl powder coating is normally applied in thinner coats by electrostatic spray or fluidized bed.

-

What are the most valuable characteristics of vinyl coatings?

Vinyl coatings offer excellent benefits for the products and surfaces they cover (and their manufacturers), including:

- Extreme durability

- Excellent insulating capabilities

- Superior resistance to chemical exposures

- High performance in a wide range of temperatures

- Powerful resistance to impacts and abrasions

- Low cost for value

-

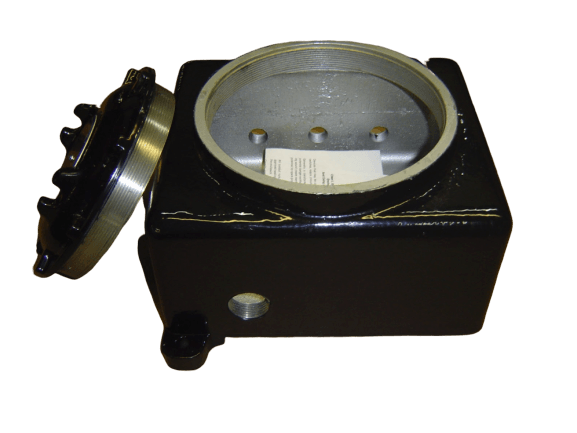

What does vinyl powder coating look like?

Vinyl coatings have a shiny, glossy finish, and, like related plastisol coatings, can be tinted virtually any color.

-

What are some common applications for vinyl coatings?

Vinyl coatings are an excellent choice to protect wire goods and similar products, such as sports helmet facemasks, appliance racks and shelving, and industrial baskets. Playground equipment, outdoor furniture, and electrical components are also frequent candidates for vinyl coatings.

LEARN MORE WITH OUR BLOGS

HAVE QUESTIONS?

Thinking of starting a project and want to know if we're the right fit to work with you? We would love to answer any question that you may have. Precision Dip Coating is located on 176 Chase River Rd, Waterbury, CT 06704, United States and can help you step in the right direction with your project. Additionally, you can email sales@precisiondipcoating.com for more information.

ISO 9001:2015 Certified

ABOUT

SERVICES

CONTACT US

CONTACT USThe information on this website is for general information purposes only. This information is not intended to create, and receipt or viewing does not constitute, a manufacturer and client relationship. Precision Dip Coating is licensed & insured for the job. Call 203-805-4564. Email with any questions you may have regarding this website, or anything associated with it.

All Rights Reserved. This website was designed, SEO optimized, and marketed by DeveloMark.